To generate a comprehensive validation report, it is important to incorporate all suitable information and facts related to the validation process. This incorporates information about the target and scope in the validation, the methodology followed, as well as tools, applications, and software program made use of.

a verification that different login/password credentials for entry are Performing and cause unique functioning privileges;

“Original qualification and periodic qualification need to be planned in the grasp document describing Each and every automatic module. Initial qualification ought to include IQ, OQ and PQ. IQ should involve the verification in the intended module requirements, the Check out of mounted instrumentation and the integration of Doing the job and servicing Guidelines during the grasp document on the module. The functionalities of the automatic module without reagents nor chemical components should be checked for the duration of OQ, which also needs to include: i) a verification with the application consumer access policy, with reference to the several attainable volume of privileges (e.g. administrators usually have the proper to modify any parameters, sequences, techniques, and so on., although operators ought to have the possibility to run dispensing applications only); ii) a verification from the program sequences, if applicable; iii) a verification of the feasible outcomes of the general electric power failure (e.g. to check for the existence and / or the necessity for an UPS; iv) a verification on the calibration position of the major elements; v) a verification of information backup and restore.

g., vehicles, computer systems, etcetera.) and, for that reason, customers should really endeavour to amass DQ doc beforehand. Each template of DQ, IQ, OQ and PQ commonly are available on-line respectively, whereas the Do-it-yourself skills of machinery/machines might be assisted possibly by The seller's education training course components and tutorials, more info or with the released steering publications, such as action-by-phase series In case the acquisition of machinery/equipment isn't bundled with on- web page qualification providers. This kind of the DIY method is usually applicable to your qualifications of software package, Laptop or computer working units along with a manufacturing process. The most important and critical activity as the last move from the exercise is to producing and archiving equipment/products qualification reports for auditing purposes, if regulatory compliances are mandatory.[citation wanted]

SOP, or Regular Running Course of action(s) are documents which offer Guidance, in a transparent and concise form, to execute a particular job. They cope with each of the functions and ways involved with the lifecycle in the preparing of the radiopharmaceutical.

By pursuing these measures, you could achieve worthwhile insights from a validation report and consider ideal steps to guarantee the quality and compliance within your processes, equipment, or computer software.

By pursuing the outlined parts, you may produce a robust validation report that process validation in pharmaceutical industry serves its function efficiently.

Aseptic functions might be validated by way of process simulation exams working with microbial advancement media, which are then incubated and examined for microbial contamination (media fill exams).

Aseptic process simulation (APS) is important for validation of the aseptic manufacturing process and…

Have a look at these process validation dialogue papers that promote discussion and build awareness on new or emerging subject areas. The papers usually point out an issue deliver the tentative exploration of remedies and options, and may propose potential up coming techniques.

In my expertise, ValGenesis is exclusive in that they are willing to share their validation documentation with us. Having the ability to use this seller documentation saved no less than 6 months off our program; which was an amazing help.

Membership discounts can be found only to latest members and therefore are meant for particular person use of the guides, not for resale.

At last, qualification protocols are aimed to confirm that a method / devices is appropriately installed, performs correctly and results in the envisioned effects. Because of this the effective outcome of a qualification protocol makes it possible for the gear being routinely employed for the planning / QC of radiopharmaceuticals, but isn't going to eradicate the necessity for periodic tests from the instrumentation through their everyday living cycle. The sort of periodic checks, their suggested frequency and obligations are precise for every meant tools, and they are normally Section of the final quality assurance programmes, that ought to be in position in just about every radiopharmacy.

Title your assortment: Name has to be under people Pick a set: Struggling to load your selection on account of an mistake

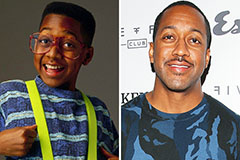

Jaleel White Then & Now!

Jaleel White Then & Now! Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Alicia Silverstone Then & Now!

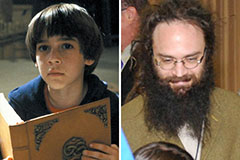

Alicia Silverstone Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now!